Features of Low Frequency Induction Furnace

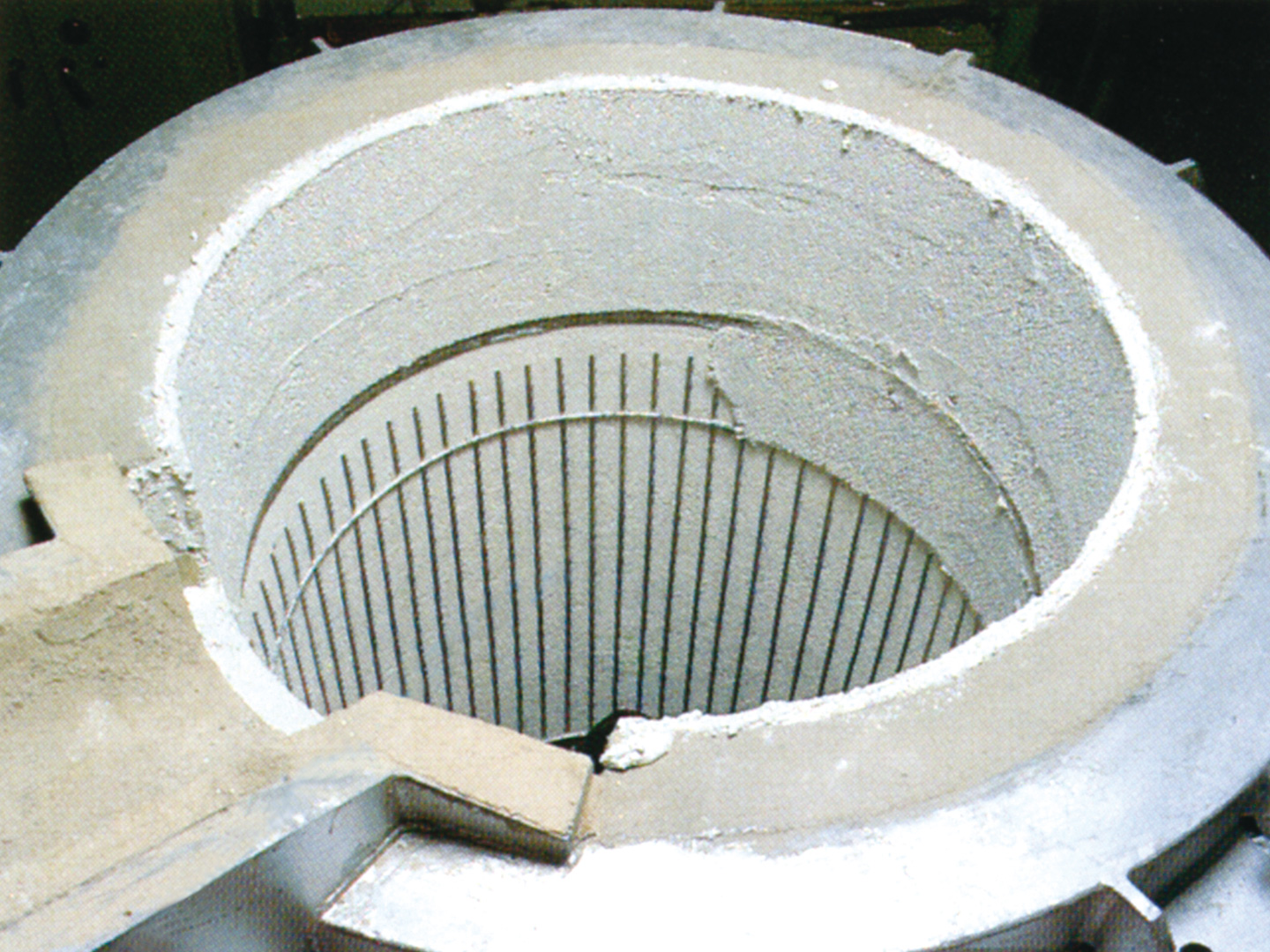

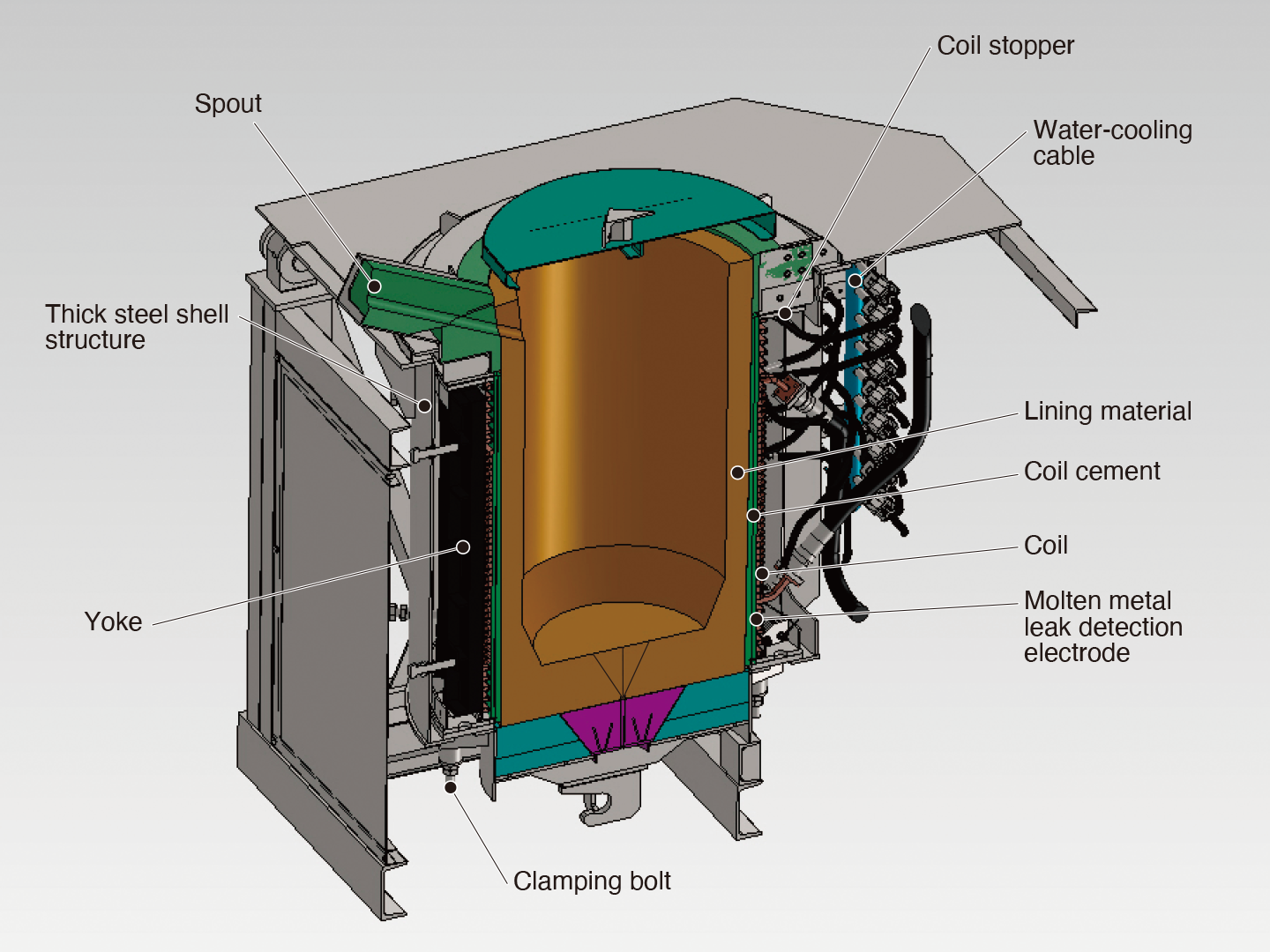

ugged and Long Life Furnace Body with Shell

Furnace body composed of thick steel shell plate is high rigidity and is suitable for the use of long term and frequent tilting operation.

Steel shell protects the heating coil from cutting wastes or scattering molten metals.

Easy Coil Replacement with Compact Coil Unit Design.

Users can easily replace the coil unit which is assembled by own strong clamping.

High Reliable Coil Insulation

Heating coil employs the insulation of high quality molded with silicon rubber and mica insulation of Class H and therefore it prevents from the short circuit accident causing of dew condensation and cutting wastes etc.

The outer surface of coil employs two layers of special insulation.

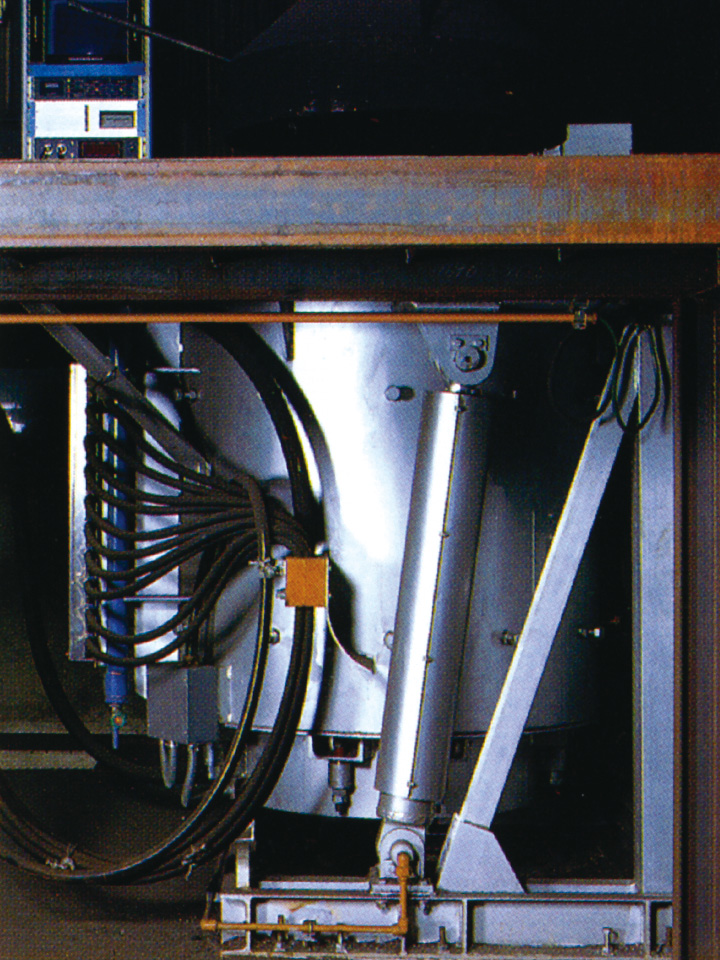

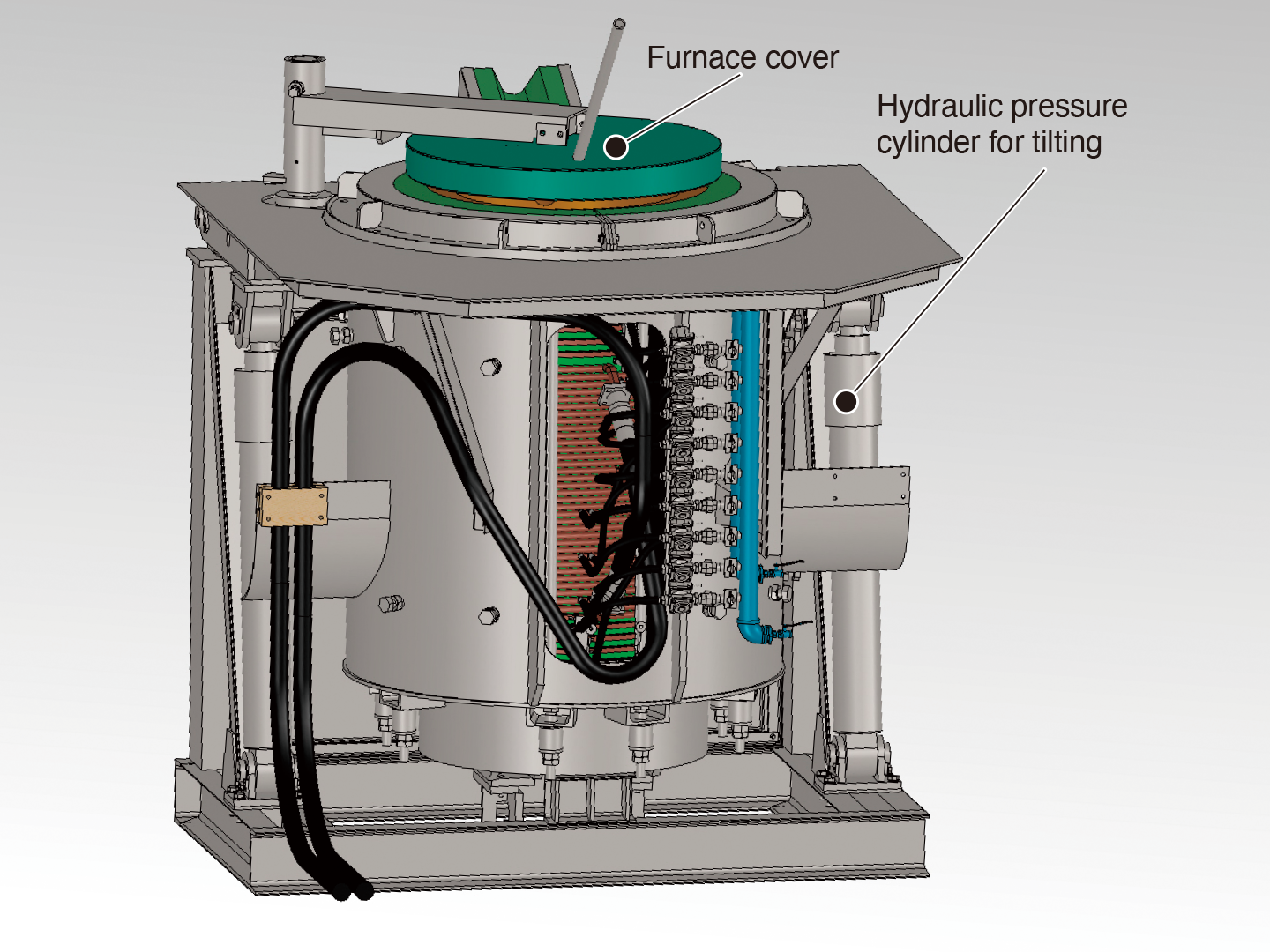

Safe and Reliable Hydraulic Tilting Device

Tilting device employs a hydraulic system of a smooth operation and hydraulic fluid of fireproof class.

High Reliable Metal Leak Detection Device

It uses a unique method to be plastered special electrodes between coil cements as well as high frequency furnace.

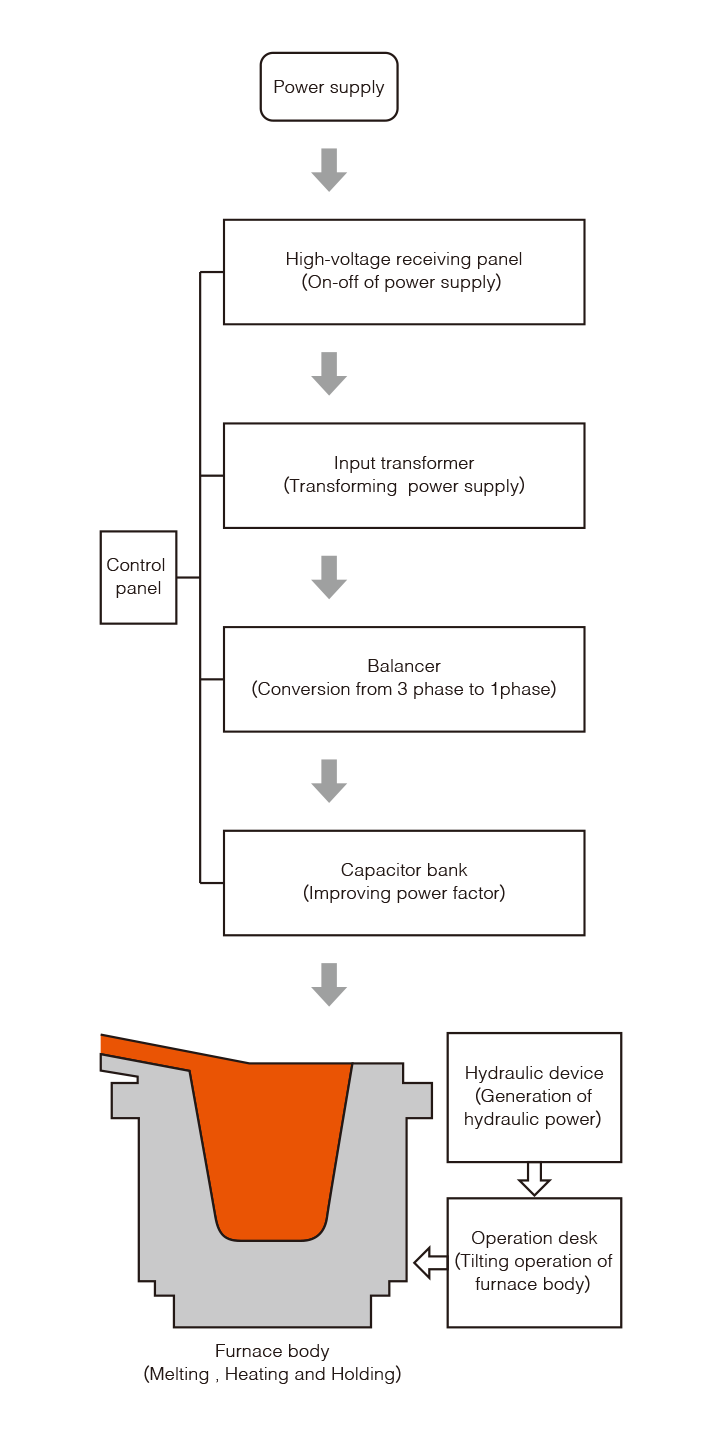

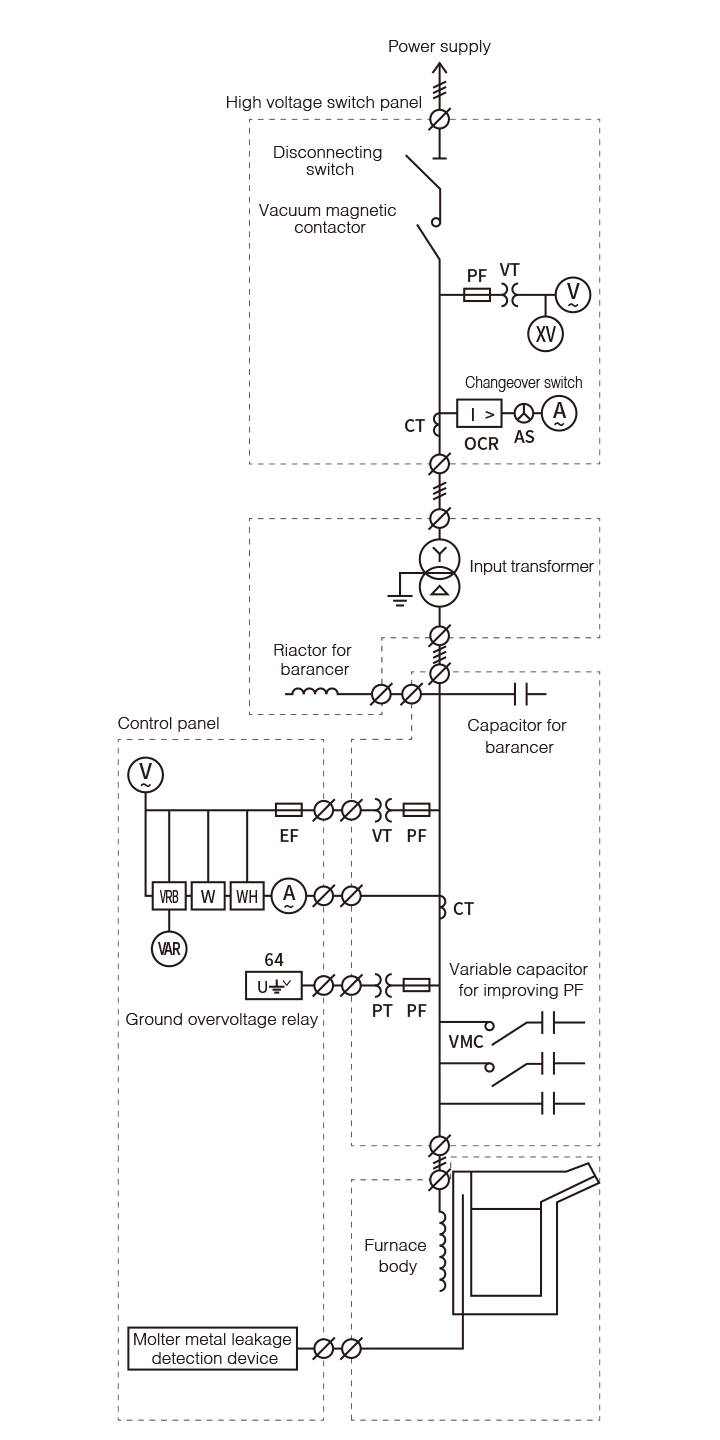

Device Configuration/Main Circuit Diagram

Device Configuration

Operation of open- close of the furnace cover by hydraulic pressure is optional.

Main Circuit Diagram

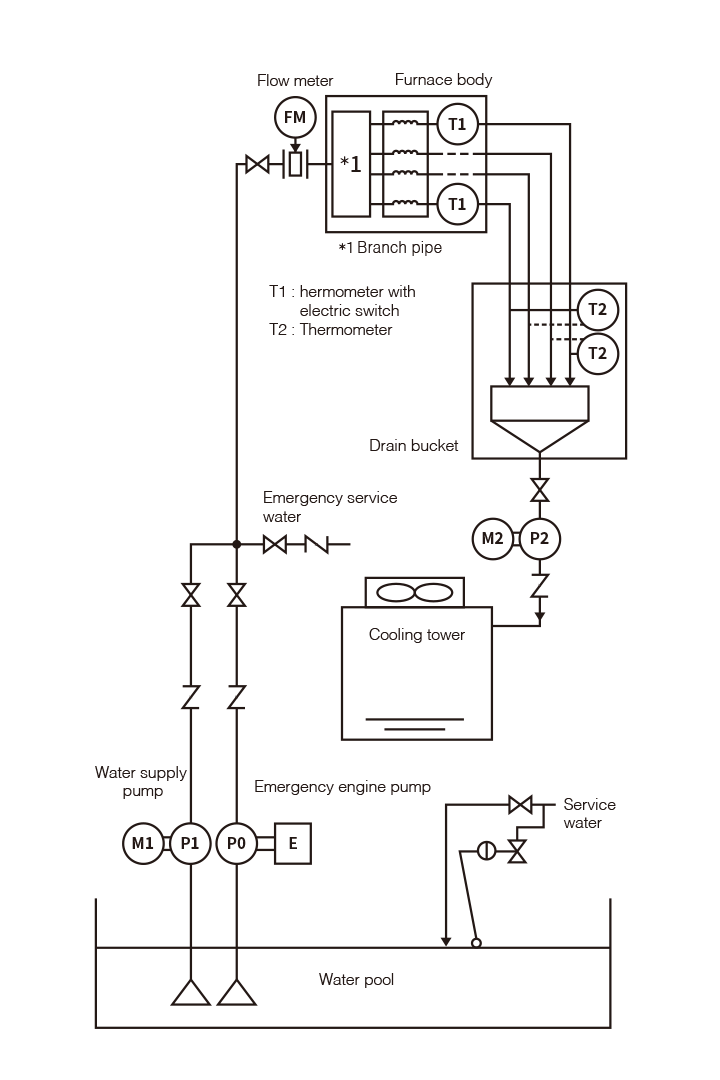

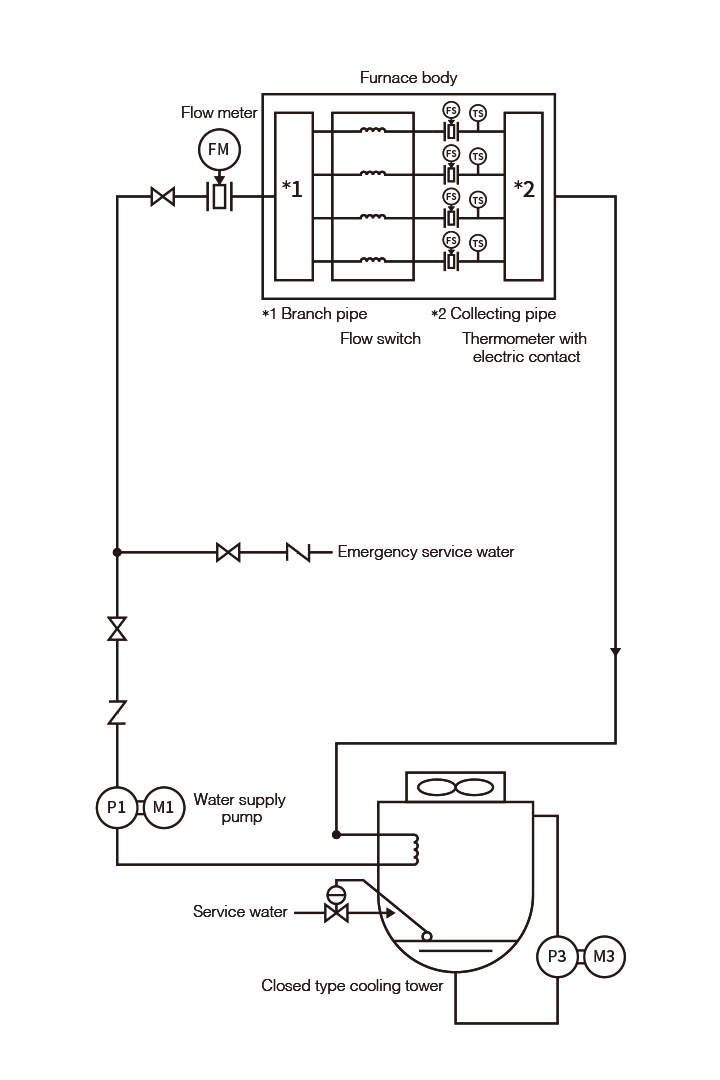

Cooling System

Open enclosure type (standard)

Closed enclosure type (option)

Characteristics

For melting cast iron

| Type | Capacity (Ton) |

Rated power (kW) |

Power consumption (kWh/Ton) |

Melting rate (Ton/h) |

Heating rate (Ton/h) |

Power consumption at heating (kWh/Ton) |

|---|---|---|---|---|---|---|

| LRS0.75-250 | 0.75 | 250 | 630 | 0.41 | 5.26 | 49 |

| LRS1-350 | 1 | 350 | 590 | 0.62 | 7.84 | 46 |

| LRS1.5-450 | 1.5 | 450 | 585 | 0.82 | 10.5 | 44 |

| LRS2-550 | 2 | 550 | 560 | 1.02 | 13.5 | 42 |

| LRS3-800 | 3 | 800 | 540 | 1.53 | 21.1 | 39 |

| LRS4-1000 | 4 | 1000 | 520 | 1.99 | 27.1 | 38 |

| LRS5-1200 | 5 | 1200 | 520 | 2.36 | 32.6 | 38 |

| LRS6-1400 | 6 | 1400 | 510 | 2.81 | 39.0 | 37 |

| LRS8-1800 | 8 | 1800 | 500 | 3.71 | 51.5 | 36 |

| LRS10-2100 | 10 | 2100 | 500 | 4.26 | 61.9 | 35 |

| LRS12-2500 | 12 | 2500 | 495 | 5.18 | 73.6 | 35 |

| LRS15-3000 | 15 | 3000 | 490 | 6.22 | 91.0 | 34 |

| LRS18-3500 | 18 | 3500 | 480 | 7.34 | 106 | 34 |

| LRS20-3800 | 20 | 3800 | 480 | 7.98 | 119 | 33 |

| LRS25-4500 | 25 | 4500 | 475 | 9.46 | 141 | 33 |

| LRS30-5200 | 30 | 5200 | 470 | 11.1 | 162 | 33 |

- Melting time and power consumption are attained when the furnace is operated with hot lining sufficiently and smelts cooled materials up to 1500℃ and molten metal is tapped about 1/3 amount of furnace capacity every time.

- Heating rate and power consumption at heating mean that molten metal is heated to 100 degrees during from 1300 degrees to 1500 degrees. In any case, the times or electric power required for charging/discharging, slag-off, ingredient adjustment, temperature measurement, etc. are not included.

For melting copper alloy

| Type | Capacity (Ton) |

電気定格 | Copper (cf.1) | Brass (cf.2) | Bronze (cf.3) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Rated power (kW) |

電源容量 (kVA) |

Melting rate (kg/h) |

Power consumption (kWh/Ton) |

Melting rate (kg/h) |

Power consumption (kWh/Ton) |

Melting rate (kg/h) |

Power consumption (kWh/Ton) |

||

| LRC-0.3-150 | 0.3 | 150 | 175 | 252 | 595 | 365 | 410 | 326 | 460 |

| LRC-0.5-200 | 0.5 | 200 | 240 | 347 | 575 | 506 | 395 | 449 | 445 |

| LRC-1-350 | 1 | 350 | 420 | 714 | 490 | 1000 | 350 | 897 | 390 |

| LRC-1.5-450 | 1.5 | 450 | 550 | 957 | 470 | 1323 | 340 | 1200 | 375 |

| LRC-2-550 | 2 | 550 | 650 | 1235 | 445 | 1692 | 325 | 1527 | 360 |

| LRC-3-800 | 3 | 800 | 900 | 1882 | 425 | 2539 | 315 | 2318 | 345 |

| LRC-5-1200 | 5 | 1200 | 1400 | 2962 | 405 | 4000 | 300 | 3692 | 325 |

| LRC-6-1400 | 6 | 1400 | 1650 | 3500 | 400 | 4745 | 295 | 4375 | 320 |

| LRC-8-1800 | 8 | 1800 | 2100 | 4615 | 390 | 6315 | 285 | 5806 | 310 |

| LRC-10-2100 | 10 | 2100 | 2500 | 5454 | 385 | 7368 | 285 | 6774 | 310 |

- Cupper are smelted from cooled materials up to 1200℃

- Brass are smelted from cooled materials up to 1100℃

- Bronze are smelted from cooled materials up to 1250℃

In any case, the discharging volume is to be 1/3 of the furnace capacity and the time or electric power required for charging/discharging, slag-off, ingredient adjustment.

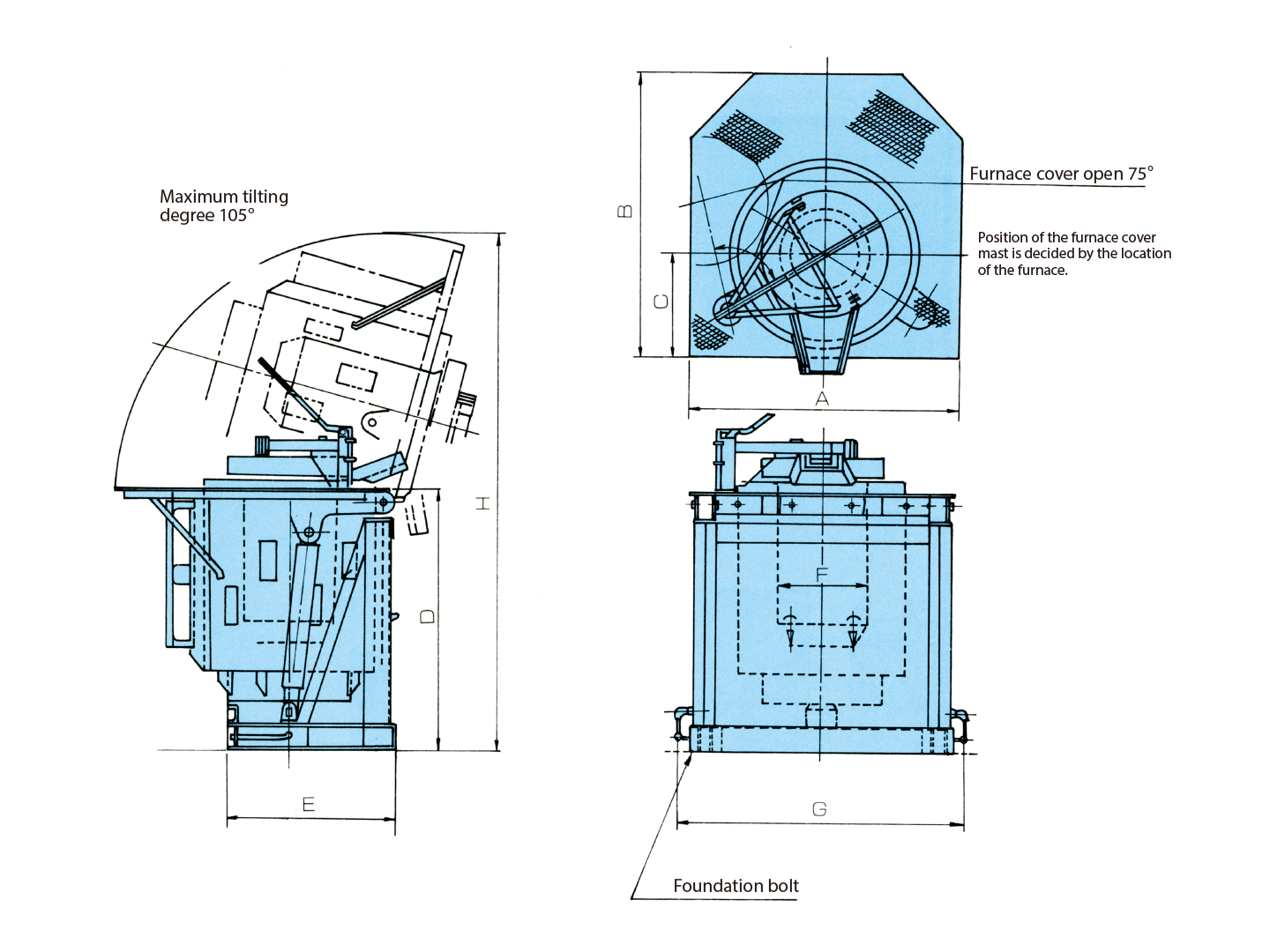

Outline Drawing

Dimensions table (Furnace capacity indicates in case of cast iron)

unit:mm

| Capacity (Ton) |

Weight (kg) |

A | B | C | D | E | F | G | H |

|---|---|---|---|---|---|---|---|---|---|

| 0.75 | 2800 | 1650 | 1665 | 595 | 1490 | 1025 | 455 | 1660 | 3005 |

| 1 | 3400 | 1700 | 1720 | 620 | 1560 | 1070 | 500 | 1710 | 3200 |

| 1.5 | 4500 | 1830 | 1850 | 650 | 1700 | 1120 | 600 | 1840 | 3430 |

| 2 | 5600 | 1900 | 2010 | 710 | 1750 | 1200 | 630 | 1930 | 3640 |

| 3 | 7200 | 2200 | 2200 | 800 | 2050 | 1350 | 720 | 2220 | 4100 |

| 4 | 10000 | 2400 | 2500 | 900 | 2250 | 1550 | 790 | 2425 | 4575 |

| 5 | 11000 | 2600 | 2600 | 950 | 2400 | 1600 | 855 | 2600 | 4820 |

| 6 | 13500 | 2700 | 2750 | 1000 | 2470 | 1700 | 910 | 2700 | 5050 |

| 8 | 18000 | 3100 | 3110 | 1110 | 2850 | 2320 | 1000 | 3150 | 5768 |

| 10 | 22000 | 3350 | 3520 | 1220 | 3000 | 2520 | 1075 | 3400 | 6328 |

| 12 | 25000 | 3350 | 3870 | 1220 | 3150 | 2520 | 1145 | 3400 | 6830 |

| 15 | 30000 | 3800 | 4150 | 1450 | 3600 | 3000 | 1230 | 3900 | 7350 |

| 20 | 35000 | 4400 | 4450 | 1550 | 4000 | 3100 | 1355 | 4500 | 8130 |

Molten metal is not included.